Clean Rooms: The Pinnacle of Controlled Environments

Date:2024-07-03

Clean Rooms: The Pinnacle of Controlled Environments

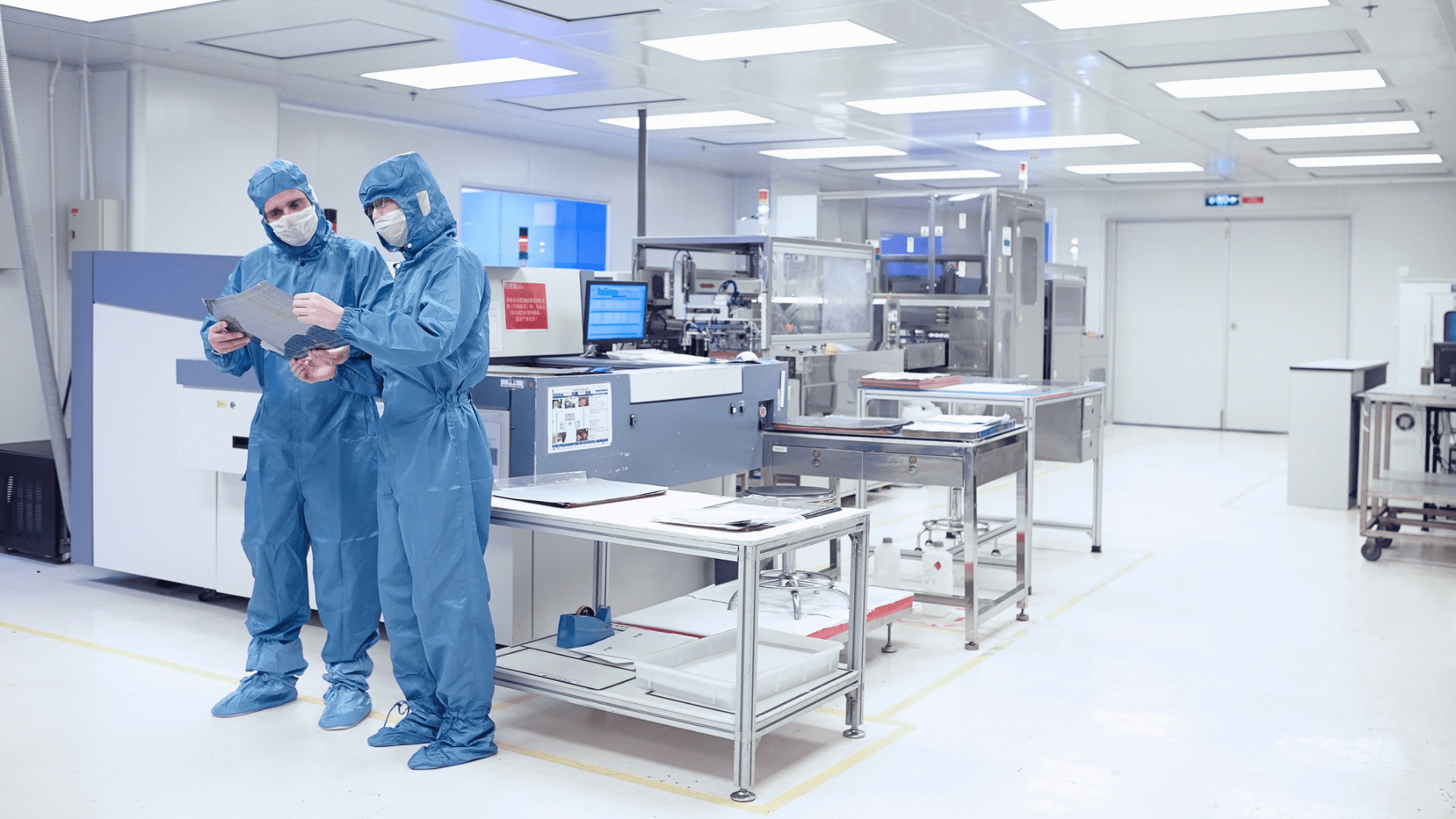

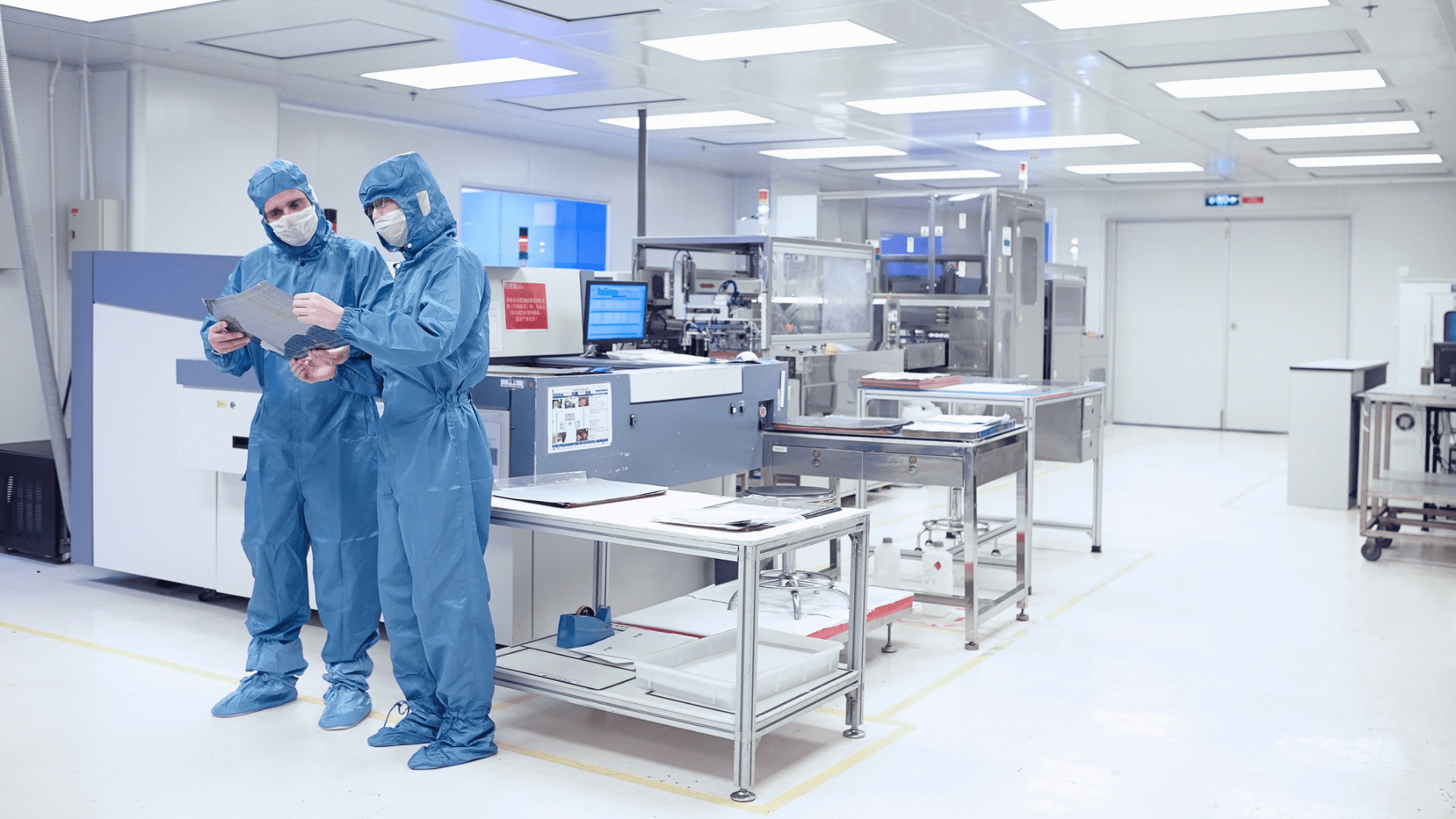

In industries where precision and sterility are paramount, clean rooms serve as the backbone of operations. These meticulously controlled environments are designed to maintain low levels of contaminants, such as dust, airborne microbes, and chemical vapors. Their significance spans across various fields, including pharmaceuticals, biotechnology, electronics, and aerospace. Let's delve into the world of clean rooms and explore why they are indispensable in today's advanced technological landscape.

What is a Clean Room?

A clean room is a controlled environment where pollutants like dust, airborne microbes, aerosol particles, and chemical vapors are filtered out to provide the cleanest area possible. The goal is to control the level of contamination, thereby safeguarding the processes or products within the room. Clean rooms are categorized by the number of particles per cubic meter at a specified particle size, as defined by ISO 14644-1.

The Importance of Clean Rooms

1. Pharmaceutical and Biotechnology Industries:

In pharmaceutical manufacturing, maintaining a sterile environment is crucial to ensure that medicines are safe for consumption. Clean rooms prevent contamination during the production of vaccines, injectable drugs, and other sterile products. Similarly, in biotechnology, clean rooms are essential for the development and production of biotechnological products, ensuring that they meet stringent regulatory standards.

2. Electronics and Semiconductor Manufacturing:

The production of semiconductors and microelectronics requires an extremely clean environment. Even the smallest particle can cause defects in the microchips, leading to failures in electronic devices. Clean rooms enable the manufacture of high-precision components by eliminating potential sources of contamination.

3. Aerospace Industry:

In aerospace, clean rooms are used during the assembly and maintenance of spacecraft, satellites, and other sensitive equipment. The controlled environment ensures that no foreign particles interfere with the delicate instruments, which could compromise their functionality in space.

How Clean Rooms Work

Clean rooms utilize a combination of high-efficiency particulate air (HEPA) filters and ultra-low particulate air (ULPA) filters to remove contaminants from the air. The air inside a clean room is continuously circulated through these filters to maintain the desired level of cleanliness. Additionally, clean rooms are equipped with specialized clothing, sticky mats, and air showers to further minimize the introduction of particles by personnel.

Benefits of Clean Rooms

1. Enhanced Product Quality:

By eliminating contaminants, clean rooms ensure that products are of the highest quality, free from defects and impurities.

2. Regulatory Compliance:

Many industries are subject to strict regulatory standards. Clean rooms help companies meet these requirements, ensuring compliance with industry regulations.

3. Increased Efficiency:

A controlled environment reduces the likelihood of contamination-related delays and defects, leading to more efficient production processes.

4. Protection of Research and Development:

For research and development, especially in the fields of nanotechnology and life sciences, clean rooms provide a pristine environment that is crucial for accurate and reliable experimental results.

Investing in Clean Rooms

As technology continues to advance, the need for clean rooms will only grow. Investing in clean room technology ensures that companies can maintain the highest standards of quality and safety in their products. Whether it's for manufacturing, research, or development, clean rooms are an essential component of modern industry, enabling breakthroughs and innovations that shape our future.

In conclusion, clean rooms are more than just spaces; they are critical environments that drive quality, innovation, and progress across various industries. By controlling contamination, they safeguard the integrity of processes and products, ensuring excellence in every aspect. Embrace the clean room technology today and pave the way for a cleaner, more precise tomorrow.

---

By understanding the importance and functionality of clean rooms, we can appreciate their role in advancing technology and maintaining high standards in production and research. Their contributions are indispensable in ensuring that industries operate smoothly and efficiently, meeting the demands of a rapidly evolving world.

Need expert advice or a quote? Reach out to us today!

WhatsApp: +86 18638188782

Mobile: +8618638188782

Email: marketing@brdecogroup.com

In industries where precision and sterility are paramount, clean rooms serve as the backbone of operations. These meticulously controlled environments are designed to maintain low levels of contaminants, such as dust, airborne microbes, and chemical vapors. Their significance spans across various fields, including pharmaceuticals, biotechnology, electronics, and aerospace. Let's delve into the world of clean rooms and explore why they are indispensable in today's advanced technological landscape.

What is a Clean Room?

A clean room is a controlled environment where pollutants like dust, airborne microbes, aerosol particles, and chemical vapors are filtered out to provide the cleanest area possible. The goal is to control the level of contamination, thereby safeguarding the processes or products within the room. Clean rooms are categorized by the number of particles per cubic meter at a specified particle size, as defined by ISO 14644-1.

The Importance of Clean Rooms

1. Pharmaceutical and Biotechnology Industries:

In pharmaceutical manufacturing, maintaining a sterile environment is crucial to ensure that medicines are safe for consumption. Clean rooms prevent contamination during the production of vaccines, injectable drugs, and other sterile products. Similarly, in biotechnology, clean rooms are essential for the development and production of biotechnological products, ensuring that they meet stringent regulatory standards.

2. Electronics and Semiconductor Manufacturing:

The production of semiconductors and microelectronics requires an extremely clean environment. Even the smallest particle can cause defects in the microchips, leading to failures in electronic devices. Clean rooms enable the manufacture of high-precision components by eliminating potential sources of contamination.

3. Aerospace Industry:

In aerospace, clean rooms are used during the assembly and maintenance of spacecraft, satellites, and other sensitive equipment. The controlled environment ensures that no foreign particles interfere with the delicate instruments, which could compromise their functionality in space.

How Clean Rooms Work

Clean rooms utilize a combination of high-efficiency particulate air (HEPA) filters and ultra-low particulate air (ULPA) filters to remove contaminants from the air. The air inside a clean room is continuously circulated through these filters to maintain the desired level of cleanliness. Additionally, clean rooms are equipped with specialized clothing, sticky mats, and air showers to further minimize the introduction of particles by personnel.

Benefits of Clean Rooms

1. Enhanced Product Quality:

By eliminating contaminants, clean rooms ensure that products are of the highest quality, free from defects and impurities.

2. Regulatory Compliance:

Many industries are subject to strict regulatory standards. Clean rooms help companies meet these requirements, ensuring compliance with industry regulations.

3. Increased Efficiency:

A controlled environment reduces the likelihood of contamination-related delays and defects, leading to more efficient production processes.

4. Protection of Research and Development:

For research and development, especially in the fields of nanotechnology and life sciences, clean rooms provide a pristine environment that is crucial for accurate and reliable experimental results.

Investing in Clean Rooms

As technology continues to advance, the need for clean rooms will only grow. Investing in clean room technology ensures that companies can maintain the highest standards of quality and safety in their products. Whether it's for manufacturing, research, or development, clean rooms are an essential component of modern industry, enabling breakthroughs and innovations that shape our future.

In conclusion, clean rooms are more than just spaces; they are critical environments that drive quality, innovation, and progress across various industries. By controlling contamination, they safeguard the integrity of processes and products, ensuring excellence in every aspect. Embrace the clean room technology today and pave the way for a cleaner, more precise tomorrow.

---

By understanding the importance and functionality of clean rooms, we can appreciate their role in advancing technology and maintaining high standards in production and research. Their contributions are indispensable in ensuring that industries operate smoothly and efficiently, meeting the demands of a rapidly evolving world.

Need expert advice or a quote? Reach out to us today!

WhatsApp: +86 18638188782

Mobile: +8618638188782

Email: marketing@brdecogroup.com

Back to List

Latest News

-

2024-12-04BRDECO Group CEO Tim in Saudi Arabia: Strengthening Ties, Building Futures

2024-12-04BRDECO Group CEO Tim in Saudi Arabia: Strengthening Ties, Building Futures -

.jpg) 2024-11-25BRD Group Concludes a Successful Showcase at Tokyo FoodTech Week 2024

2024-11-25BRD Group Concludes a Successful Showcase at Tokyo FoodTech Week 2024 -

.jpg) 2024-11-13BRD Introduces Aluminum Alloy Insulated Great Wall Panels: A Revolutionary Building Material

2024-11-13BRD Introduces Aluminum Alloy Insulated Great Wall Panels: A Revolutionary Building Material -

2024-11-06BRD Group Engages with Middle East Market at SaudiBuild 34th Edition

2024-11-06BRD Group Engages with Middle East Market at SaudiBuild 34th Edition -

.jpg) 2024-10-23BRD Group Secures Major Cold Storage Project with Bangladesh's Bashundhara Group

2024-10-23BRD Group Secures Major Cold Storage Project with Bangladesh's Bashundhara Group