Categories

Hot products

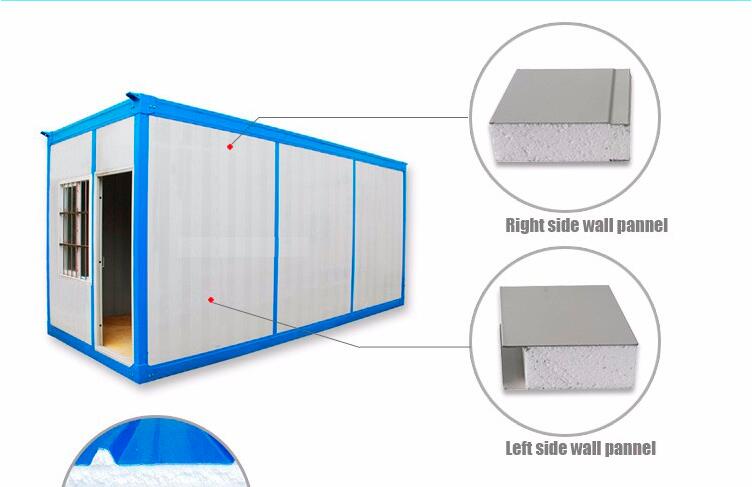

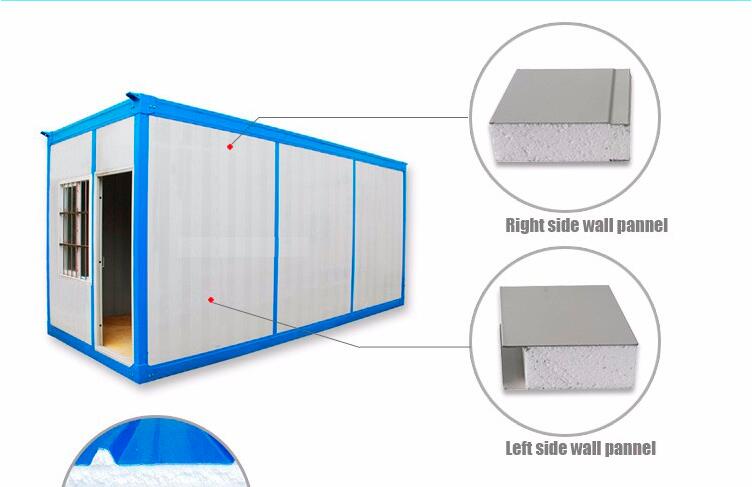

Description of Polystyrene Wall Panels

Polystyrene Sandwich Panel also called EPS Sandwich Panel. The top & bottom Surface of this panel is Galvanized & pre-painted steel sheets, core material is polystyrene, it is formatted by laminating and pressing with 2 components PU glue. The sandwich panel is featured with temperature keeping, hot & sound insulation, anti water and fire resistant. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

eps panel systems Comprise of Pre-Fabricated Composite sandwich panels with high density EPS Converted to Lamellar as core and profiled/ plain,colour coated galvanized steel / Galvalume Steel sheet facing on both sides, complete with joint sealants and fixing ancillaries.

eps panel systems Comprise of Pre-Fabricated Composite sandwich panels with high density EPS Converted to Lamellar as core and profiled/ plain,colour coated galvanized steel / Galvalume Steel sheet facing on both sides, complete with joint sealants and fixing ancillaries.

Specifications

| No | ITEMS | DESCRIPTION |

| 1 | Structures | -The upper and bottom sheets are respectively zinc-plated & color-coated steel sheets, thickness : 0,3-0,6mm-Core material: EPS, Density: 11-40 kg/m3. |

| 2 | Width | -Effective width 1000mm, width: 1030mm |

| 3 | Length | -Depend on customer requirement (<12m transport within) |

| 4 | Thickness | -Wall panel: 50mm, 75mm, 100mm, 150mm Roof panel: 50mm, 75mm, 100mm, 150mm |

| 5 | Color | -Blue, Ivory, White, Grey… |

| 6 | Applications | – Prefabricated house, Industrial sheds, Warehouses, Commercial complexes, indoor/outdoor stadiums, cold storage, buildings & indoor partitions etc |

Features of Polystyrene Wall Panels

Advantages of Polystyrene Wall Panels

- Major savings in energy cost.

- Light weight and easy installation.

- High standard of thermal insulation.

- Can be produced rapidly and on demand in the required quantity and length.

- Can be easily transported to wherever they are needed.

- Lower cost solution compared to traditional building materials.

- Saves construction and maintenance cost.

- Provides durability and long life.

Advantage

-

SUPER FLAME RETARDATIONThe coefficient of thermal conductivity is 0.023w/(m.k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits.

SUPER FLAME RETARDATIONThe coefficient of thermal conductivity is 0.023w/(m.k), which ensures better thermal insulation efficiency. In practice, this effectively keeps the building absorbing heat and brings enormous economic benefits. -

ECONOMICALGreat flame retardation and the complete removal of cold bridges (during the rafter installation), do help reduce heating bills.

ECONOMICALGreat flame retardation and the complete removal of cold bridges (during the rafter installation), do help reduce heating bills. -

DURABLEBRD PU sandwich panels are the most durable thermal insulating material in the construction industry. Under the normal maintenance, its service life is the same with buildings.

DURABLEBRD PU sandwich panels are the most durable thermal insulating material in the construction industry. Under the normal maintenance, its service life is the same with buildings. -

ECOLOGICAL100% of the material is recyclable and the panels are friendly to the environment at the production and disposal stages.

ECOLOGICAL100% of the material is recyclable and the panels are friendly to the environment at the production and disposal stages. -

EASY AND QUICK INSTALLATIONCompared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.

EASY AND QUICK INSTALLATIONCompared with traditional thermal insulation methods, BRD use less material while the installation process is less time-consuming and labor-demanding leading to lower building costs.

Application

PU sandwich panels are applied as external walls and internal division walls, installed vertically or horizontally on single- or multi-span structure. Thanks to its hidden joint the panel ensures very aesthetic look of the wall or façade. In particular the panels can be applied in

-

Industrial buildings,

-

Store houses and logistic centres,

-

Commercial buildings and offices,

-

Food industry facilities,

-

Agricultural objects

-

Sport halls.

(1).jpg)

.jpg)

(2).jpg)

.jpg)

(1).jpg)