Categories

Hot products

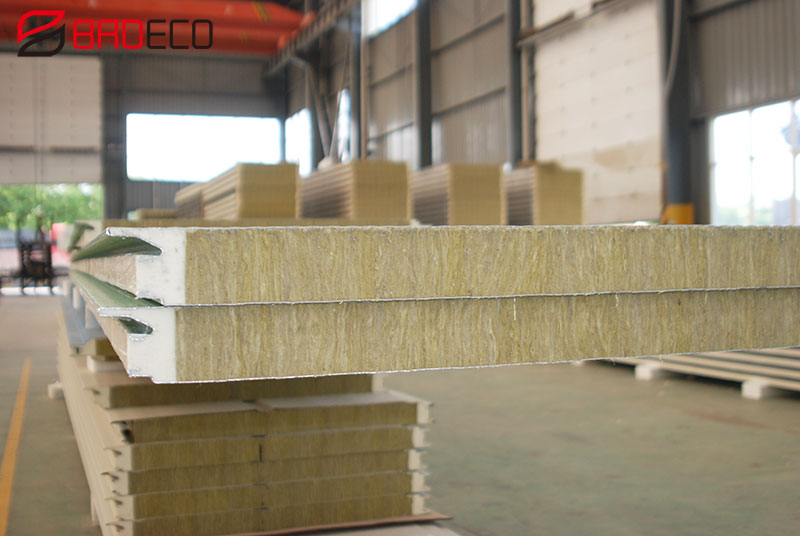

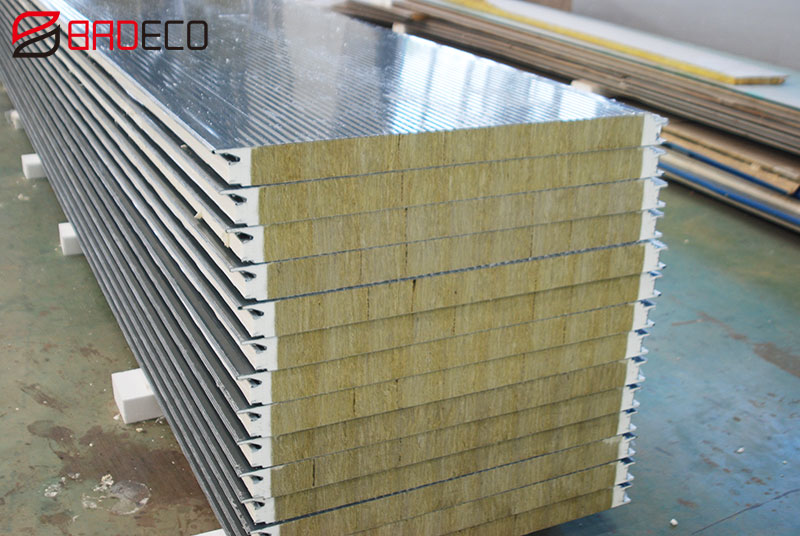

Description of Rockwool Insulated Roof Panels

The top and bottom of rockwool composite panels is galvanized pre-painted steel. Core material is rock wool with density at 100 or 120kg/m3, the rock wool is upright against the surfaces. There are high strength vesicant between rock wools and surfaces. This product is featured with full anti-firing, more heating and sound insulation. It is widely used as the wall or roof for cold storage, industrial workshop, public building etc.

Rock wool sandwich panel is applicable to project with fairly high demand upon fire protection . The rock wool fibers plum to the color steel sheet plates . high density strip rock wool crisscross with the length of the color steel plates . All of this guaranteed the rock wool sandwich panel have a good bearing capability . Wall panel and roof tile has 50mm , 75mm , 100mm , 125mm , 150mm foam with 0.326mm , 0.4-0.6mm steel sheet widely use for prefabricated house, construction site, building, warehouse, worker camp, office ect .

.jpg)

It is low cost and thermal insulation , fireproof , sound insulation .The fix width of wall panel or roof tile has 1150 and 950mm , length is no limited but less than 12000mm because of the transportation . The surface metal coat could adopt galvanize aluminum steel sheet , galvanized aluminum zinc color steel sheet and the galvanized color steel sheet.

Rock wool sandwich panel is applicable to project with fairly high demand upon fire protection . The rock wool fibers plum to the color steel sheet plates . high density strip rock wool crisscross with the length of the color steel plates . All of this guaranteed the rock wool sandwich panel have a good bearing capability . Wall panel and roof tile has 50mm , 75mm , 100mm , 125mm , 150mm foam with 0.326mm , 0.4-0.6mm steel sheet widely use for prefabricated house, construction site, building, warehouse, worker camp, office ect .

.jpg)

It is low cost and thermal insulation , fireproof , sound insulation .The fix width of wall panel or roof tile has 1150 and 950mm , length is no limited but less than 12000mm because of the transportation . The surface metal coat could adopt galvanize aluminum steel sheet , galvanized aluminum zinc color steel sheet and the galvanized color steel sheet.

Specifications of Rock Wool Insulation Board

| Panel characteristics | Panel thickness [mm] | ||||||

| 50 | 75 | 100 | 150 | 200 | |||

| Functions |

|

||||||

| Standard Facings |

|

||||||

| Steel thickness [mm] | 0.4, 0.5, 0.6, 0.7, 0.8 | ||||||

| Rock wool core material | density 100 / 120 kg/m³ | ||||||

| Panel areal weight [kg/m²] | 15.50 | 18.50 | 22.5 | 30.00 | 36.50 | ||

| Thermal conductivity λD[W/mK] | 0.043 | ||||||

| Thermal transmittance U-value [W/m²K] |

0,63 | 0,48 | 0,39 | 0,27 | 0,20 | ||

| Acoustic insulation [dB] | 27 | ||||||

| Length [mm] | As customized | ||||||

| Effective width [mm] | 1000mm(option 950,1150) | ||||||

| Fire resistance | - | EI 90 / E 120 | E 120 / EW 60 | ||||

| Corrosion resistance | C1, C2, C3 | ||||||

Features of Rock Wool Sandwich Panel

- Acoustic Performance

Fire Performance

BRD panels do not contribute in any way to the spreading of fire. It does not shrink, stretch or deform when exposed to fire. It does not cause smoke or any burning droplets in case of fire. It significantly contributes to improved fire safety.

- Resistance to moisture

Storage

To store for long duration, BRD panels should be stored indoor. If stored outside, the panels should be stacked clear of ground and covered with a securely anchored weather proof sheet. The panels should not be left exposed to weather.

- Non Toxic

- Environmental impact

Usage of Sandwich Panel Rockwool

Can be used for wall,roof,floor and partition of cold storage, mobile house, suburban housing, suburban housing,industrial plants, warehouses, supermarkets, hospitals, stadiums, activities room,clean workshop and reconstruction residence, villa, kindergarten, commercial building, remodeling of old structures, heat insulation fire places, airport, etc.

Advantage

-

COST SAVING & DURABILITYThe rock wool sandwich panel insulation stone wool is made from rock, making it naturally durable and stable over the lifetime of a building. As the unique physical structure, rock wool panel is not affected by changes in temperature or humidity. This means the owner can create a pleasant and stable temperature year after year, while saving energy and money for cooling/heating.

COST SAVING & DURABILITYThe rock wool sandwich panel insulation stone wool is made from rock, making it naturally durable and stable over the lifetime of a building. As the unique physical structure, rock wool panel is not affected by changes in temperature or humidity. This means the owner can create a pleasant and stable temperature year after year, while saving energy and money for cooling/heating. -

FIRE SAFETYHave you ever seen rock burn? Neither have we. Rock Wool Panel Products are rated Non-combustible. Basalt stone wool adopted to Sandwich Panels is fire-protecting insulation material, it's fibers’ resistance to high temperatures, will limit the buildings to fire or spread. Using Rock wool sandwich panel will improve the building's fireproof performance, protect life and property safety.

FIRE SAFETYHave you ever seen rock burn? Neither have we. Rock Wool Panel Products are rated Non-combustible. Basalt stone wool adopted to Sandwich Panels is fire-protecting insulation material, it's fibers’ resistance to high temperatures, will limit the buildings to fire or spread. Using Rock wool sandwich panel will improve the building's fireproof performance, protect life and property safety. -

SOUND INSULATIONSound is tough to get through rock. Rock wool sandwiched panels are the most effective acoustic insulation used in construction. Installing Rock wool panel provides a real reduction in external noise, our rock wool panels allow builders to design the right acoustic environment for each space, whether it’s a workshop, concert hall, air clean room, or residential house.

SOUND INSULATIONSound is tough to get through rock. Rock wool sandwiched panels are the most effective acoustic insulation used in construction. Installing Rock wool panel provides a real reduction in external noise, our rock wool panels allow builders to design the right acoustic environment for each space, whether it’s a workshop, concert hall, air clean room, or residential house. -

FAST CONSTRUCTIONRock wool sandwich panels and accessories are produced in full accordance with the building layout drawing, it is fast and flexible to install on the construction site. The construction period can be shortened by more than 40%. Therefore, rock wool sandwich panel is ideal for fast constructed prefabricated buildings, such as industrial warehouse, container house, prefab buildings.

FAST CONSTRUCTIONRock wool sandwich panels and accessories are produced in full accordance with the building layout drawing, it is fast and flexible to install on the construction site. The construction period can be shortened by more than 40%. Therefore, rock wool sandwich panel is ideal for fast constructed prefabricated buildings, such as industrial warehouse, container house, prefab buildings. -

LONG LIFE TIMERock wool sandwich panel is produced by the automatic production machine at a constant temperature, all the raw materials and process are in strict accordance with the international quality management system. which means the quality of the product is stable, can guarantee the life time of 25 years.

LONG LIFE TIMERock wool sandwich panel is produced by the automatic production machine at a constant temperature, all the raw materials and process are in strict accordance with the international quality management system. which means the quality of the product is stable, can guarantee the life time of 25 years.

.jpg)

.jpg)

.jpg)

.png)